In many industries, bulk material transport is almost the heart that keeps everything running. Whether you work with chemicals, fertilisers, aggregates or mineral loads, choosing between a chain conveyor and a belt conveyor can make the difference between a smooth process and one full of complications.

Sometimes it seems that both solutions do ‘the same thing’, but nothing could be further from the truth. Each has its own way of working, its strengths and its limitations. In this guide, we tell you what really matters when it comes to making a decision. And we do so using Sinfimasa’s experience, where we have been designing customised Redler-type chain conveyors for years, adapted to processes that do not allow for improvisation.

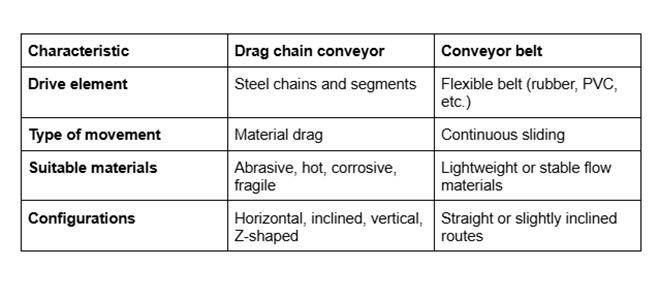

Operating principle and key differences

To make a good decision, it is first necessary to understand how each system works. It is not just a question of aesthetics or space, but of engineering.

In practice, these differences completely change the way the system works. For example, an abrasive material that can destroy a belt in a few weeks moves without difficulty on a chain conveyor. And when the installation is small or has complicated routes, a Z-shaped layout that a belt could never handle fits perfectly on chain equipment.

Advantages of drag chain conveyors over belt conveyors

Although conveyor belts work very well in thousands of installations, chain conveyors gain ground when the process requires more than just a simple transport line. Here are the most common reasons:

- Robustness you can feel. Chain conveyors are made for harsh environments: high temperatures, aggressive products, abrasion… They hold up without affecting the entire system. That peace of mind is appreciated, especially when you can’t afford unexpected downtime.

- Less maintenance and more accessible. Belts require frequent tensioning, adjustments and replacements. In contrast, chains offer more stable and simpler maintenance. It doesn’t disappear, but it does become much more predictable.

- Total material containment. When you handle products that generate dust, that may be hazardous or that simply must not be lost along the way, chain conveyors make all the difference. Their enclosed design reduces spillage and prevents contamination of the environment.

- It adapts to complicated spaces. Old facilities, narrow corridors, the need to overcome uneven surfaces… Many projects do not have an ‘ideal’ layout. This is where the chain demonstrates how versatile it can be.

- Multiple outlets on the same route. One of those advantages that seem small until you need them. Chain conveyors allow unloading at multiple points, which is very useful when feeding different lines.

When to choose a drag chain conveyor?

There are situations where there is no doubt: the chain is the logical choice.

- When the material ‘rules’. If you work with abrasive, dense or complex products, chains tend to offer a much longer service life.

- If you need cleanliness or containment. Fine, chemical or flammable materials… When you need to ensure that nothing escapes, the closed design of the chain conveyor provides great peace of mind.

- When the route is not straightforward. Steep slopes, changes in height or Z-shaped trajectories that a belt cannot handle. These cases are the natural terrain of the chain.

- When the project is 100% customised. Each plant is a universe unto itself: space constraints, structural interference, integration with silos or dosing units… The chain conveyor can be easily customised.

Conveyor belt limitations

Conveyor belts remain a great option in many scenarios. But, like everything else, they have their weaknesses:

- It wears out quickly with certain materials. Abrasion is its natural enemy. Sand, gravel, clinker or recycled glass can drastically shorten the belt’s service life.

- It requires frequent maintenance. Tensioning, alignment, roller checks… In plants with limited staff, this can be a daily challenge.

- Little design flexibility. Belts are practical, yes, but only when the layout is simple. As soon as turns, slopes or multiple discharge points are required, problems arise.

- Higher risk of spillage. Especially with powdery or fine-grained materials. Lateral control is more complicated and product loss is more common.

Which system is best suited to your plant?

There is no universal answer. Conveyor belts work wonderfully for light, linear flows with little wear and tear. However, when the process is more demanding, whether due to the material, temperature, space or level of safety required, chain conveyors clearly stand out.

At Sinfimasa, we have been designing customised systems for years and we know how important it is to get it right the first time. Each conveyor is adapted to the process, the material and the physical reality of the plant, without generic solutions or improvisations.

If you are considering renovating or installing a new conveyor system, we will be delighted to help you. Our engineering team can analyse your case and propose the solution that best suits your needs.